Lean Tip #616 – When Setting and Achieving Goals Write Them

Down

A very simple tip and a very effective one, too. Write your

goals on a piece of paper and paste it somewhere which can remind you everyday

that you need to get them. No, I am not suggesting that you get paranoid. If

you think that they won't go out of your mind and you don't need to jot them

down, it's good. But if there's a slightest chance that you'll lose sight of

them, it's better to have them written down and take a look everyday.

Lean Tip #617 – When Setting and Achieving Goals Make an

Action Plan

So you have set goals, written them down and now you are all

set to start working towards achieving them. First step - make an action plan.

There could be more than one method to achieve a goal. Which one suits you ?

Decide on it.

Lean Tip #618 – When Setting and Achieving Goals Welcome

Failure

If you learn to welcome failure and keep going, I think

there's nothing which can stop you from achieving your goals. I don't know

anyone who had an absolute smooth run and became successful. Failure is an

important part of the entire process. Welcome it. Learn from it.

Lean Tip #619 – When Setting and Achieving Goals Track

Progress

Extremely important. If you don't track progress, you don't

get an idea if you are going the right way and if you would ever achieve it in

the time frame you had set in your mind. So track your progress everyday. There

are various methods and tools to track progress.

Lean Tip #620 – When Setting and Achieving Goals Persist

Persist. Don't give up. As I mentioned, there could be many

paths leading to the same destination. Try out different methods. Learn and

improve. Be patient. Be persistent.

Lean Tip #621 - It takes time for a change to become an

established habit.

It will probably take a couple of months before any changes become

a routine part of your life. That's because your brain needs time to get used

to the idea that this new thing you're doing is part of your regular routine.

Lean Tip #622 - Pleasing other people doesn't work.

The key to making any change is to find the desire within

yourself — you have to do it because you want it, not because someone else

wants you to. It will be harder to stay on track and motivated if you're doing

something out of obligation to another person.

Lean Tip #623 - Roadblocks don't mean failure.

Slip-ups are actually part of the learning process as you

retrain your brain into a new way of thinking. It may take a few tries to reach

a goal. But that's OK — it's normal to mess up or give up a few times when

trying to make a change. So remember that everyone slips up and don't beat

yourself up about it. Just remind yourself to get back on track.

Lean Tip #624 - Read, Listen and Learn

Setting goals is not about accomplishing things as much as

it is about personal growth. You see, when you set goals that are challenging,

you will have to become a better person in order to accomplish those goals. That

is why it’s important that you read, listen and learn how you can become better

in every area of your life.

Lean Tip #625 – Achieving Your Goals Requires Determination

One of the most common characteristics of people that

constantly achieve their goals is that they are determined and relentless. They

don’t give up. Imagine being relentless in the face of obstacles and

challenges. See yourself blasting through the roadblocks and moving boldly to

your goals. You already have that ability in you, you just have to dust it off

and start using it.

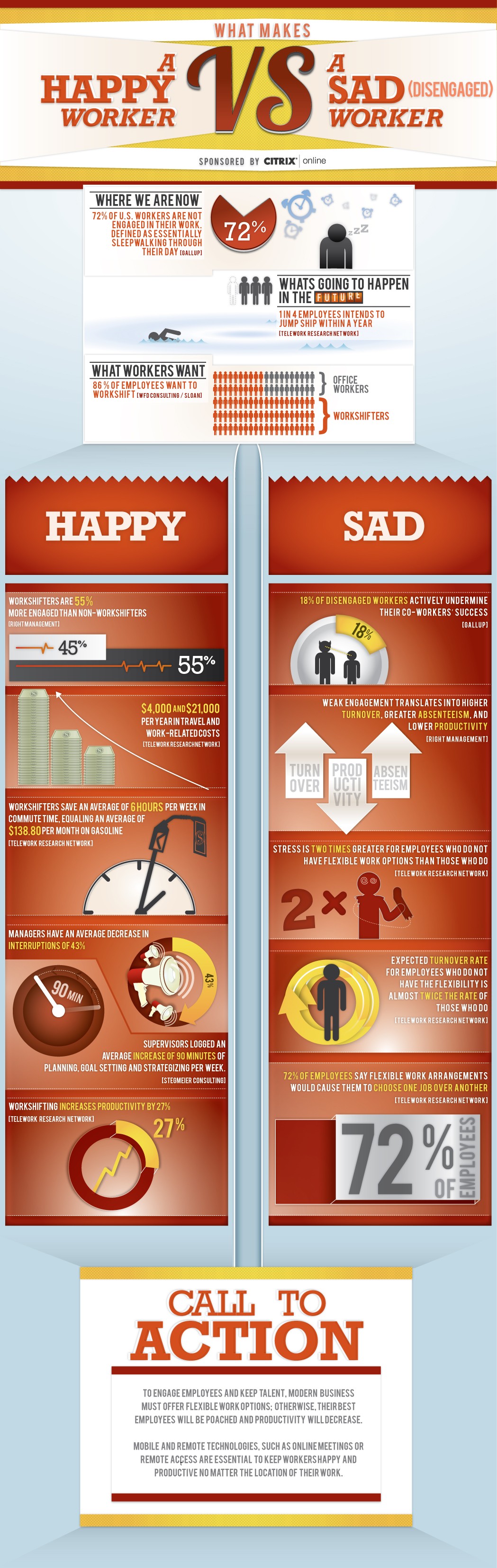

Lean Tip #626 - Get Energized About Work.

Getting energized about work usually results from a couple

things. Primarily if a work culture is fun to be in, it’s a place you look

forward to going because the people (and leadership) are authentic, caring and

fun. And teams that are energized with what they are doing get excited by the

opportunities that a day may bring.

Lean Tip #627 - Planning is the Basic Step for Success.

You won’t know where you are going unless you know where you

want to go. Confusing? Well that’s exactly how your business would be, if you

do not keep things simple and organized. Planning is the basic step to succeed

in business and planning accurately and developing strategies will lead you to

a healthy and growing business. That means reframing the top down objectives in

your organization. Don’t just work with only the large goal in mind. Set immediate

and short term goals that fire up your team. Celebrate achieving those goals

and adjust as the culture and needs change… We live in a very fluid business

world where things change fast. Create a team that is able to change along with

it.

Lean Tip #628 - Strive to Learn Something New Every Single

Day.

It is easy to get bogged down in the same old, same old. In

order to fully realize potential, you’ll have to add knowledge, skills, and

experience. Don’t expect your potential to spring forth in a final draft; it

takes time to hone your skills and build your confidence. This could come from

formal schooling, from the school of hard knocks, or from both. Either way,

your education is the house your realized potential will live in. The

opportunities for learning are multiplying every day in this

information/technology age. Learn at least one new thing every day. Improve

your mind and enhance your skills. Never stop learning.

Lean Tip #629 - Work Smarter Not Harder.

Productivity comes from working smarter, not harder. That is

the difference between effectiveness and efficiency. You can be effective

without being efficient, but, the key to productivity is to do both. Sometimes,

those job inefficiencies are not very obvious. However, if you can specifically

identify them, then those inefficiencies can be eliminated and staff can become

more productive. By distributing the tasks and responsibilities around, you not

only become more flexible and able to respond to changes more quickly, but you

involve more people in the improvement process. This can increase work

satisfaction as well.

Lean Tip #630 - Devote Time Each Month to Employee

Development.

Most people want to learn and grow their skills at

work. Encourage experimentation and taking reasonable risk to develop employee

skills. Get to know them personally. Ask what motivates them. Ask what career

objectives they have and are aiming to achieve. You can make their career. In

order to get the most from your employees, you need to invest time and

resources in their development. Annual performance reviews simply aren’t

enough. Make a point to sit down with each employee on a monthly basis (or more

frequently, if possible) and provide them with specific feedback and areas of

improvement.