Thursday, November 24, 2022

Be Thankful This Holiday

Monday, November 21, 2022

Build a Culture of Gratitude at Work

Thanking your

employees when you think they’ve genuinely performed may boost their commitment

to delivering more. When your team knows that you won’t be stingy with your

praise when they’ve made extra efforts, they will trust you enough to go the

extra mile without having to be pushed.

Why don’t we

say “thank you” at work? Perhaps it’s because we don’t like to thank people for

something we feel is just an ordinary part of each day—a part of what’s

expected? Or we don’t want to cross that line of kissing up or showing

favoritism? And everyone knows thank-you emails are taboo.

But, building a

culture of gratitude at work has benefits to both the person receiving and the

person expressing the thanks:

1. Saying

“thank you” shows people you value them. It doesn’t just acknowledge someone’s

effort, thoughtfulness, intent or action … it acknowledges the person themselves.

When we receive thanks, it gives us a heightened sense of self-worth. But, it

doesn’t stop there. It also triggers more helpful behaviors toward both the

person we are helping and toward other people.

2. Gratitude

also has benefits for the person expressing gratitude. Research demonstrates

that taking time to consider and express the things we’re grateful for has a

powerful, positive effect. If practiced regularly, it can keep you healthier

and happier. Higher levels of gratitude shown in people’s daily lives results

in better sleep and lower anxiety and depression. Feeling and expressing

gratitude activated brain regions that make us feel good.

Offering

gratitude and expressing messages of thanks to your team can truly motivate

your team members and improve the workplace. Pay attention to good work, and

offer thanks whenever you identify a job well done. Continue to apply team

appreciation and establish it firmly in your workplace culture.

This helps to

create a more satisfactory work environment where your employees are more

inclined to feel appreciated and happy. Doing so increases engagement,

participation, self-esteem and can even positively impact your bottom line. You

may also feel more effective as a leader and likely more connected to your team

and what they’re doing.

Gratitude is

powerful. It’s up to the people with power to clearly, consistently, and

authentically say thank you in both public and private settings. And the

benefits go far beyond just letting someone know you appreciate their efforts.

A simple “thank you” can trigger more good work and positive feelings for

everyone involved.

Friday, November 18, 2022

Lean Quote: Inspiring Gratitude in the Workplace

Gratitude is a

key factor for living a life filled with positivity. Practicing gratitude in

the workplace brings about many positive effects. Feeling valued and

appreciated is a fundamental human need of employees. Appreciated employees

tend to be more loyal, productive, and satisfied in their roles.

Promoting

gratitude in the workplace can be a bit of a challenge. It’s hard for employees

to remember to practice gratitude – especially during a rough day at the

office. The easiest way for you to help employees feel and express gratitude is

by leading by example. Here are a few ways to cultivate gratitude at your

company:

Look for

opportunities to celebrate success.

This could be a newsletter shout-out to an employee who contributed to their

team or throwing an appreciation party for employees to celebrate their tenure.

Be sure to look out for small successes that will make employees feel special.

Support

peer-to-peer recognition.

Encourage employees to create shout-outs or thankyou notes for their

colleagues. Provide employees with printouts that they can fill out and give to

one another. Ask employees to give out at least one thank-you note a week.

Get

employees involved in community service projects. Volunteering is a powerful way to promote

gratitude. Provide employees with information on local organizations that are

looking for volunteers. If you are able to, coordinate a team outing for

employees to volunteer together.

Offer

education about benefits of gratitude.

Send out blog posts, articles, and research studies on the benefits of

gratitude. Employees will be more inclined to practice gratitude once they

understand its benefits.

Reinforce

random acts of kindness at work.

Recognize employees who go out of their way to help a co-worker or make someone

smile. Kindness is contagious!

Although

gratitude might sound like a cheesy topic, research has proved that it can

truly impact a person’s mental and physical wellbeing, as well as their work performance.

Maintaining an attitude of gratitude releases dopamine in the brain, which in

turn boosts feelings of wellbeing, increases optimism, and improves physical

health.

Employees who

feel appreciated by their employers and colleagues tend to be happier and more

enthusiastic with their work. They are motivated to do a better job and

contribute to the success of their company.

Wednesday, November 16, 2022

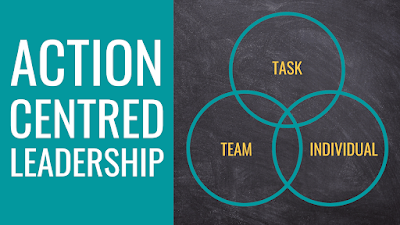

Action Centered Leadership

Back in 1973,

British leadership expert John Adair published his action centered leadership

model. It’s also known as the “three-circle” model. He developed this model

during the 60s to show a more relevant and modern leadership approach.

Model of

Action-Centered Leadership is developed by focusing on what leaders do and is

based on the following principles:

- The task can only be performed by

the team rather than any one person/leader

- The team will excel only when all

members are fully developed

- The members must be motivated and

need to challenge the task

- Leadership can be taught; if one

person can do something, then others can also learn to do it

Adair’s action

model can be represented by Adair’s three circles, which illustrates his three

core management responsibilities. Each of these three elements plays an

important role in the leadership, and only when all three are balanced

properly, the leader is going to be successful and effective:

1. Achieving

the task: Task is the

foundation that creates the need for leadership. Without the task, there is no

need for any leadership. Every leadership role is developed because there is a

goal in mind, and someone needs to be in charge of directing the team toward

that goal.

2. Managing

the team or group: To

achieve tasks, the team is essential. The team is made up of individuals having

different skills and experiences, and they collectively contribute to the

business goal. A leader’s key responsibility is to motivate the team members to

put in their best for the best possible performance towards completing the

task.

3.

Managing/Empowering individuals: The

leader is responsible for each individual employee, his progress, and

development. Forgetting about individuals as humans and treating them only as a

resource that must do what is best for the organization is a big leadership

mistake. Extracting the best effort from each person on the team requires

treating them with trust and respect as individuals that they are. Each

individual needs recognition by means of salary, fun, and challenging work and

responsibility.

Adair focused

on 8 key functions for action centered leadership to happen.

- Defining the task: here we are creating clarity and

setting the direction. We should use SMARTER goals to help achieve these

results.

- Planning: it’s about having a strategy to

achieve the task. We need to look at all options and take suggestions from

the team when planning what to do and how to do it.

- Briefing the team: we need to communicate with the

team regularly. Here we are providing feedback and accepting

input.

- Controlling what happens: we will have control measures in

place to maintain standards. These measures will ensure we are monitoring

the situation and taking action when needed.

- Evaluating results: it’s important that we’re

reviewing individual and team performance and tracking milestones. We also

need to identify areas of improvement.

- Motivating individuals: we are responsible for providing

recognition and praise, using motivators effectively. Therefore, we

are keeping the team driven to achieve the results.

- Organizing people: All leaders need to have the

capability of arranging the team into a highly functional unit. We do this

by using time management, delegation, and development to keep people

on track.

- Setting an example: here we need to lead by example.

We cannot expect the team to follow our lead if we are

inconsistent.

As you can see,

all 3 elements of Task, Team and Individual feature throughout these key

functions.

Some criticize

the hierarchical approach that Adair’s theory takes, claiming it does not allow

for modern organizational structures that tend to be more linear. Current

thinking suggests that leadership should focus on empowerment, enabling and

encouraging innovation, whereas Adair takes a more traditional approach which

could be seen as authoritarian.

However, others

claim that the simplicity of Adair’s model makes it ‘timeless’ and the simple,

practical framework provides clarity to the role of a leader. The simplicity of

Adair’s ideas results in this model being relevant to leaders, irrespective of

the sector they work in and the task being completed.

Successful

implementation of Adair’s model will enable leaders to

- Build morale

- Achieve

strong results

- Improve work

quality

- Develop

strong teams

- Improve

productivity

Overall, I

highly recommend learning this simple model and using action centered

leadership. This approach will help us focus on those 3 key elements better. It

also allows us to practice those 8 functions that Adair highlighted to allow

this model to work even better. Give it a try and see the benefits.

Monday, November 14, 2022

Lean Tips Edition #195 (#3136 - #3150)

Here is the next addition of tips from the Facebook page:

Lean Tip #3136 – Organize Your Materials and Parts for Efficient Retrieval

The amount of money (and time) that is wasted through a lack of organization can be staggering.

This particularly true if materials or components are stored at various points in the manufacturing process – with time spent retrieving these items making up a significant portion of your costs.

Making sure your storage and warehouse facility is well organized will improve this “picking” process, which can be further improved through the use of suitable parts or picking bins.

The increased speed at which the parts or components arrive at your manufacturing line will lead to increased productivity, as well as helping to avoid delays and production even stopping whilst waiting for items. This is also true for reducing picking errors, which organization can again help with.

And better organization can also highlight shortages of any stock more quickly, again preventing downtime.

Lean Tip #3137 – Maximize the Use of Space

Maximizing the use of space can be a surprisingly effective way to improve your manufacturing productivity. The amount of time employees spend moving from one area to another has a direct impact on the efficiency of your manufacturing.

By rearranging your factory floor to put commonly used equipment or machines closer to each other, to keep of stock of parts or components nearer to where they will be needed, and make each trip as efficient as possible (i.e. move multiple items with a tote, and ensure picking errors are minimized through well-organized stock and parts bins) can all have a big impact.

Ultimately, you may wish to consider rearranging your manufacturing floor layout in order to create a smoother workflow or both components, product and people.

Lean Tip #3138 – Troubleshoot and Maintain Machines

Regular maintenance and troubleshooting of your machinery and equipment is crucial in maintaining and improving productivity.

This is also where it is important to train – and then trust – the employees that use these on a daily basis. They will be the first to spot an issue, and if familiar with the equipment can potentially fix the issue with little disruption caused.

Besides this, knowing the signs that something is not running well (or even at capacity) can be critical in avoiding larger problems. It is far easier to keep a machine running through maintenance and care than it is to repair it once something has failed.

Lean Tip #3139 – Cut Down on Quality Waste (Material Scrap)

Every damaged component that cannot be used costs money. Every unfinished product costs money. Every item returned by your customers costs money – and hurts your brand and business reputation.

It is therefore essential to protect items when being stored (picking bins) and when being moved (handling totes).

And whilst it is also understandable that mistakes can and will occur, if this becomes too frequent then getting to the root cause and identifying a fix (either training / recruitment, new processes, equipment etc.) is critical.

Lean Tip #3140 – Remember to be Realistic With Your Goals

Expectations from your customers, tight deadlines and pressures from external factors (for example logistics and delivery times) can all lead to targets becoming distorted and often unachievable.

In cases such as this, it is important to manage expectations diplomatically and ensure corners are not cut – whether this is through safety or quality. This could lead to employees become demotivated, which can lead to worsening of productivity rather than improvements.

As a result, once you have a full picture of your current productivity, set realistic goals that focus on the quality of output, punctuality and that do not compromise safety.

And involving employees and gaining their feedback on initiatives can help them feel engaged and valued too.

Lean Tip #3141 – Start by Eliminating Waste.

This is one of the core principles of lean manufacturing. Typically, you may use a value stream analysis to identify wasteful activities occurring at the plant. At the same time, you can intensify efforts to find more efficient ways to add value to the company’s product line.

Lean Tip #3142 – Reduce Unnecessary Inventory.

The cost of maintaining excess inventory generally outweighs the potential benefits you might realize. It can tie up resources, slow down response time and complicate quality-control issues. Overstocking may become particularly problematic if some of the inventory eventually becomes obsolete-which is often the case.

Lean Tip #3143 – Extend Employee Autonomy.

Give more employees authority to make decisions and provide them with the tools and methodology for doing so. You can take this step even further by establishing teams to measure work progress and improve techniques. Frequently, companies find that viable solutions may be presented by employees below the management level. Plus, this kind of involvement can improve morale and performance.

Lean Tip #3144 – Focus on Continual, Long-Term Improvement

If you have succeeded in implementing Lean across your value stream(s), then you must continue with the good habits built during the transition. A critical aspect of Lean is continuous learning and improvement. In a sense, there is no ‘final’ goal except to simply removing (and preventing) wasteful processes and delivering value to the customer. Be it a change in manufacturing technology or even complacency, new wasteful processes could emerge in the future.

Lean Tip #3145 – Take the Time to Plan Your Road Map

Once you’ve made the decision to go all in on lean, it will be tempting to jump in head first. But, just like getting buy-in from your stakeholders, every minute you spend planning will save you time (and frustration) down the road. Plus, you need a map so you know where you’re going.

Lean Tip #3146 – Ask the 5 Whys to Improve Your Problem Solving Culture

Ready to get to the root cause of whatever ails your process, with your whole team on board? Start by asking why. In fact, plan to ask it a solid four more times as part of the 5 Whys, a Lean Six Sigma strategy that will move you past the symptoms to the heart of the problem. When you include coworkers and other stakeholders in offering alternative answers to the stream of whys, the collaborative effort can go a long way in fostering a problem solving culture that embraces change and values input from all.

Lean Tip #3147 – Use Standardized Work to Scale Your Business

Manufacturers stick to a standard process because doing the same thing over and over minimizes errors and waste. Similarly, when you create a checklist for every task, product, and process in your organization, you’re making your team’s work standardized, reducing variation and the competition of individuals’ preferred methods of completing projects. This standardization of workflow, responsibility, quality, and interaction with the customer is essential as you grow your business and expand your workforce. Even the scope, timing, and content of meetings can be standardized. This is how you establish best practices and continually improve on the way to scaling your business.

Lean Tip #3148 – Make Continuous Improvement a Goal for Your Business

One of the things that you need to have in mind all the time is your business and your industry keeps changing. You need to be quick in adapting your business to these changes. And this is where continuous improvement plays an important role. As you adapt to the changing environment, you should take what you already learned and change things for the better.

The reality is that there are always areas to be improved when you have a small business. From production to customer service, accounting or operations.

Lean Tip #3149 – Collect Performance Data and Act on It

Data collection on your production performance has great value. It can help you connect the dots when you discover inefficiencies. Measuring and tracking activity provides you with insights that can contribute to waste elimination and continuous improvement.

Combining this data into dashboards allows many eyes to view and assess it. For example, if throughput is down, you need to investigate why. You can look at data from all these streams, and you may find that a piece of equipment is underperforming. You’ve found the root cause and can address it.

Lean Tip #3150 – Keep Your Eyes Open to Improvement Opportunities

You won’t always work on strategy changing projects, but there’s usually the opportunity to make small improvements everywhere. By regularly making small improvements, you’ll witness a significantly more capable process long term. The sum of the parts really can be greater than the whole.

Given

advances in technology, best practice and changing customer needs, there will

always be a better way. So make sure you are constantly looking out for these

opportunities and encourage others to do the same.

Friday, November 11, 2022

Lean Quote: Lessons from Our Veterans

On Veterans Day

we take time to honor those who fight our nation’s wars. This is a time to

honor our veterans, and one of the most important ways we can do that is to

learn from their experiences.

Here are a few

universal lessons to learn from our veterans:

1. We must

appreciate our lives no matter what you happen to be going through. Whatever

you need to do so is already within you.

2. We must

exercise our Free Will. Make your life count and enjoy the satisfaction of

knowing that you did not give up as you fought your own enemies…that is how

dreams turn into reality and miracles begin to occur.

3. We must keep

hope alive. Hope is intangible, but the ramifications of not having it can

devastate many lives; it is the nudge that we need when we least want it, and

the salvation when we least expect it. Hope is the fabric we have weaved

through years of knowledge, laughter, tears and pain.

4. We must

always believe in ourselves and in our innate power to heal. So doubt your

doubts, not your mind, and do what you must to do more than just exist. We owe

it to those who have sacrificed so much, but most of all, we owe it to

ourselves.

Though one day

a year is not enough to show our gratitude for all that they have done, may we

honor and say thanks to all veterans this Veteran’s Day. Remember to always

keep them in your prayers for we are indebted to them for their commitment and

loyalty to our country. They deserve our affirmation and respect.

Wednesday, November 9, 2022

Why Project Management Is Critical for Business Profitability

Introduction

Managing a project is a multifaceted process that requires planning, scheduling, reporting, and tracking. Gaps in communication, resource allocation, or backup plan can affect project progress and business profitability. This article sheds light on the importance of project management and the pivotal role it plays in ensuring business profitability.

What Is Project Management?

Project management is the application of certain techniques, skills, and tools to achieve the final goal of the project. It involves planning and organizing the project to produce the desired outcome within the stipulated timeframe. The project management lifecycle consists of four rudimentary stages: initiation, planning, execution, and closure.

Over the past decade, project management has evolved through several stages. The evolution was driven by the need to deliver the project more quickly and efficiently. Most managers have switched from emails and spreadsheets to project management software. To ensure smooth project flow, it’s necessary to meet future contingencies that could derail the project.

Top Reasons Why Project Management Is Critical for Business

Profitability

● Clear Objective to Improve Competence

Setting clear objectives and a realistic timeline is the first step towards project success. By breaking the project into smaller tasks and prioritizing them appropriately, the team gains clarity about what needs to be done. If the objective is ambiguous, the project is more likely to see scope creep, missed deadlines, and, eventually, cost overrun. In the absence of project management and defined goals, the teams may misplace project priorities, causing missed deadlines and budget leaks.

● Better Project Planning Helps Staying Top of the Deliverables

Project management requires allocating

resources in the best possible ways. With proper utilization of budget and

resources, you are more likely to complete the project in time. On the other

hand, in the absence of a proper plan, you may risk wasting resources and time.

It’s better that the project manager discusses the budget, timeline, and objectives with stakeholders and clients. Together, they can outline a roadmap by keeping all aspects in mind.

Project planning involves assigning responsibilities to team members, streamlining workflow, and gearing up with a backup strategy. This way, the project completion strategy can be re-assessed and re-aligned in the event of any contingency,

● Project Management Ensures Alignment of Project with Business Strategy

Often, organizations overlook how the project aligns with the business strategies. Effective project management not only navigates the planning and execution of the project but also ensures that all the tasks and goals of the project resonate with the organization’s strategy, vision, and objective. This alignment also keeps the project manager and the stakeholders on the same page, ensuring frictionless collaboration across the team.

● Keeping Deliverable Quality in Check

As teams rush towards meeting project

deadlines, it’s possible for quality standards to suffer.

Since quality is critical for client satisfaction and the organization’s brand reputation, project management needs to play a key role in ensuring quality at all stages of the project.

To sum up, project management not only completes a project on time but also ensures that the quality of the output is assessed periodically.

● Right Project Management Methodology Step up the Game

Regardless of the level of project complexity, proper planning and execution are indispensable for project success. The organization must consider aspects like team dependencies, the team size, the project timeframe, resource allocation, contingency likelihood, and the request frequency from stakeholders.

Project management methodologies facilitate

proper project planning to address all such issues. These methodologies are the

set of rules that guide how to plan, execute and manage the project. There are

many methodologies, and each comes with its own paradigm. After assessing, the

project manager can select and implement a method that suits the project

requirements. In short, implementing the right project management methodology

can improve the team's competence, thereby ensuring project success.

● Project Management Save Time and Resources

One of the top concerns for any business is to accomplish the project within the stipulated time and budget. This is where well-organized project management and planning comes in. It helps allocate the right resources on the right task that preempts resource wastage, missed deadlines, and cost overruns. Effective project planning helps you analyze the project journey, spending, resource utilization, bottlenecks, deadlines, etc. Armed with this data, one can evaluate how achievable the deadlines are and re-shape the project journey to ensure seamless execution.

● Better Decision Making with Project Management

When the project manager has clear visibility into the project's progress, they can effortlessly make smart decisions that benefit the project. Project management provides insight into who is working on which task, where the resources are being spent, what the priorities are, and whether the project is on track. Equipped with this knowledge, businesses can make the right decisions to optimize the project workflow and mitigate the bottlenecks before they aggravate.

Conclusion: Project management streamlines the project flow and facilitates goal attainment in time, thereby ensuring the project’s success. This, in turn, enables organizations to achieve business profitability.

Author Bio: Sonika Malviya works as a content writer at Replicon and loves to write about technology

trends.