Recently, I reviewed Mike Rother's Toyota Kata book. In doing so I came across the Toyota Kata website. The site is dedicate to the practice of mastering the improvement kata as explained in his book.

This website has a number of great resources at your disposal but probably the most notable is the Improvement Kata Handbook. This is a great companion to the Toyota Kata book and can be used train and develop improvement kata thinking and acting in your company.

Mike Rother suggests a 3 step process to get started with improvement kata:

I would encourage you to thoroughly review this site and take advantage of this training material. I am sure you will find this information very informative and valuable along your journey. Keep learning, practicing, and sharing.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

Tuesday, June 28, 2011

Monday, June 27, 2011

The Role of a Lean Leader

My Friend Matt Wrye recently wrote about his role as an internal Lean consultant. He talked about the struggle some management places on Lean leaders between just doing it and influencing change. This got me thinking about my own experience, why this struggle occurs, and what the true role of a Lean leader should be.

Like Matt, I too have found myself in both types of roles. I believe this struggle with how the role is defined has a lot to do with the level of knowledge by management. So let me clarify by knowledge I mean true understand of Lean thinking as a business or management process that goes beyond improvement tools to capture employee development and engagement. I say management because it is often not just one person but a collection of managers that share a similar thinking and approach.

The level of involvement in Lean by the management team often shapes the role of the Lean leader. In my experience the less knowledgeable the management about REAL Lean (Bob Emiliani’s term) the more they think of it as a set of tools the more they want you to just do it. These are the managers that are usually hands-off with Lean and want to see the short term gains to demonstrate they are improving the process. They are focused on the results and outcomes and not the means by which we achieve them. This task oriented approach to management unfortunately is only sustainable while the doer is doing.

However those managers who truly know Lean understand the benefit comes from developing people to think and improve their own process the more they define the role as influencing or coaching. As Mike Rother said in Toyota Kata management must focus on how solutions are developed. Develop, via practice with coaching, the capability in people to develop new solutions. In this view the Lean leader can have the biggest impact coaching or influencing the process of improvement to capture the ingenuity of those in the organization.

In my experience being a coach is the most important aspect of a Lean leader. They are not the ones to come in and do it for you. They are the ones to show you how to do it with confidence so that you will be able to do it for yourself. A Lean leader must be relentless in teaching and expecting learning through actual practice.

The best analogy of a Lean leader that I have heard is related to agriculture. The Lean leader is a farmer not a hunter. Farmers take the long view, and win in the long term. Hunters take the short view, get early gains but ultimately die out. Farmers are shepherds and Lean leaders should do the same.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

Friday, June 24, 2011

Lean Quote: Leadership Requires Persistence

On Fridays I will post a Lean related Quote. Throughout our lifetimes many people touch our lives and leave us with words of wisdom. These can both be a source of new learning and also a point to pause and reflect upon lessons we have learned. Within Lean active learning is an important aspect on this journey because without learning we can not improve.

Persistence means not giving up when faced with a challenge. It is the ability to stick with a difficult task and cope with frustration.

Nowhere is the importance of persistence more relevant than in leadership

Effective leaders never give up because something runs into obstacles, faces challenges or is difficult. They evaluate the idea or program, and if they feel it is important, they take every possible step to bring it to fruition. This may be difficult because they will face the naysayers who tell them to give up or forget about it, and that is often demotivating.

Achieving any great goal cannot be done overnight. It takes hard work. There will undoubtedly be obstacles that must be overcome. Someone must hold the vision and inspire others by rolling up his or her sleeves and working to make progress. Someone must lead.

Persistence is often related to positive attitude. Someone without strong beliefs or lacking confidence will generally stop fighting for ideals. True leaders realize that it is only by fighting for, and not giving up on ideals, that they can ever be a true effective leader.

What may separate leaders among others, is their persistence to do the right things - even if these are not what they want, even if they don't feel like doing it and even if all seems to be against them.

Persistence to do the right things - will not be that easy. It will require your inner will power. Mere brute force will not do it for you - it will be a game of the mind. The stronger your resolve, the more you will persist - and the more your chances of success.

I think above all us, leadership requires persistence.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

"If you live long enough, you'll make mistakes. But if you learn from them, you'll be a better person. It's how you handle adversity, not how it affects you. The main thing is never quit, never quit, never quit." — Bill Clinton

Persistence means not giving up when faced with a challenge. It is the ability to stick with a difficult task and cope with frustration.

Nowhere is the importance of persistence more relevant than in leadership

Effective leaders never give up because something runs into obstacles, faces challenges or is difficult. They evaluate the idea or program, and if they feel it is important, they take every possible step to bring it to fruition. This may be difficult because they will face the naysayers who tell them to give up or forget about it, and that is often demotivating.

Achieving any great goal cannot be done overnight. It takes hard work. There will undoubtedly be obstacles that must be overcome. Someone must hold the vision and inspire others by rolling up his or her sleeves and working to make progress. Someone must lead.

Persistence is often related to positive attitude. Someone without strong beliefs or lacking confidence will generally stop fighting for ideals. True leaders realize that it is only by fighting for, and not giving up on ideals, that they can ever be a true effective leader.

What may separate leaders among others, is their persistence to do the right things - even if these are not what they want, even if they don't feel like doing it and even if all seems to be against them.

Persistence to do the right things - will not be that easy. It will require your inner will power. Mere brute force will not do it for you - it will be a game of the mind. The stronger your resolve, the more you will persist - and the more your chances of success.

I think above all us, leadership requires persistence.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

Wednesday, June 22, 2011

Lean. There's an App for That.

In this new age of hand held technology you frequently hear "There's an app for that" in reference to some task you are trying to do. Well, I suppose Lean thinking shouldn't be any different. The Lean Enterprise Institute introduced an app as another way to stay connected with them. With this free app, you can easily access the latest news and information about LEI and the lean community, including books, workshop calendars, blogs, tweets, webinar audio, videos, photos, and more.

One thing I like about this app is the community feel LEI tries to create with this app. This is not surprising since LEI is about creating value and building a strong Lean community. They have a fan wall that allows you to post a comment, you can leave comments about books and other posts, and you interact with other users of the app. Doing this and more on the app earns you points. The top 10 points earners are highlighted on the app.

This app has been out for sometime on the iPhone platform but I am an Android guy and this app is newly released on Android. If you are looking a Lean app for your smartphone or tablet I would recommend that you check out this app. I believe you will find value in it.

One thing I like about this app is the community feel LEI tries to create with this app. This is not surprising since LEI is about creating value and building a strong Lean community. They have a fan wall that allows you to post a comment, you can leave comments about books and other posts, and you interact with other users of the app. Doing this and more on the app earns you points. The top 10 points earners are highlighted on the app.

This app has been out for sometime on the iPhone platform but I am an Android guy and this app is newly released on Android. If you are looking a Lean app for your smartphone or tablet I would recommend that you check out this app. I believe you will find value in it.

Tuesday, June 21, 2011

Toyota Kata: Managing People for Improvement, Adaptiveness, and Superior Results

I usually have quite a list of books to read. This is compounded by all those who would like me to review their book. I enjoy learning and reading so this isn't a bad situation it just means that it can take a while to get to some books. I finally got to Mike Rother's book Toyota Kata and wish I had gotten to it sooner.

and wish I had gotten to it sooner.

A kata is a routine or behavior pattern that is deliberately practiced, whereby it becomes second nature. This is done to develop particular skills and mindset. The term kata is found mostly in the study of Asian martial arts.

Toyota Kata defines management as, "the systematic pursuit of desired conditions by utilizing human capabilities in a concerted way." Mike Rother contends that

defines management as, "the systematic pursuit of desired conditions by utilizing human capabilities in a concerted way." Mike Rother contends that Toyota

- A kata for improvement or problem solving.

- A kata for coaching

The "Improvement Kata" is a set of behavior guidelines for which a lot of discipline is needed. It is not learned in a classroom but by doing, through repeated practice. Therefore, everyone in Toyota

He states it is exactly the 'Improvement Kata' and 'Coaching Kata' that enable Toyota Toyota

- In consideration of a vision or direction…

- Grasp the current condition.

- Define the next target condition.

- Move toward that target condition iteratively, which uncovers obstacles that need to be worked on.

Rother argues that the "Kaizen Event" approach to improvement is not effective or sustainable because, at best, each process area will only get one or two bursts of improvement in a year. This is not continuous improvement and does truly engage the workforce.

Instead he argues for constant daily improvement - a "kata" – or a simple PDCA routine which is enacted every day by everyone in the process, and supported and coached by managers and team leaders who have roughly 50% of their time allocated to teaching this approach to improvement. Small step-by-step improvements are more effective over time than occasional kaizen bursts, and have a significantly greater impact on the organization culture - creating an environment of involvement and improvement.

In this management approach a primary job of leaders and managers is to develop people so that desired results can be achieved. They do this by having the organization members (leaders and managers included) deliberately practice a routine, or kata, that develops and channels their creative abilities.

The book's underlying message is that when people practice and learn a kata for how to proceed through unclear territory, they don't need to fear the obstacles, changes and unknowns they encounter. Rather than trying to hold onto a sense of certainty based on one's perspective, people can derive confidence from a kata for working through uncertainty.

Toyota Kata focuses on change and improvement, and explains how they are not an aspect of management, but the essence of it. He debunks project management, action lists, budgets and a host of other traditional management fundamentals, and replaces them with an entire organization constantly engaged in small improvements

focuses on change and improvement, and explains how they are not an aspect of management, but the essence of it. He debunks project management, action lists, budgets and a host of other traditional management fundamentals, and replaces them with an entire organization constantly engaged in small improvements

The book covers these five main interlocking topics:

- The role of vision and direction in continuous improvement.

- Critical context for the "classic lean tools" as target conditions.

- The problem solving kata, and how it differs from what most of us do.

- The coaching kata, really describing how management engages.

- A proposal for teaching the problem solving and coaching kata to a management team.

Toyota Kata is an excellent and very well written book that really adds something new to the existing Lean literature. Anyone who has been on the Lean journey will immediately and easily relate to the material Toyota Kata contains. It explains how

is an excellent and very well written book that really adds something new to the existing Lean literature. Anyone who has been on the Lean journey will immediately and easily relate to the material Toyota Kata contains. It explains how Toyota

This is a book for practitioners who actually want to create a sustainable lean organization. I guarantee you will read this book several times, and each time you'll discover something new.

Monday, June 20, 2011

Pull Systems: An Essential Lean Element

The Association For Manufacturing Excellence (AME) is committed to enterprise excellence through shared learning and access to best practices. As a proud member and leader in the Northeast Region I had the opportunity to share a best practice last fall on pull systems. I have talked about this pull system before but AME recently published an article in Target Magazine about this event that you should read.

The article was written by Jeff Schaller, a professor of operations management at Eastern Connecticut State University. In brief:

There is a lot of valuable information in this article that goes well beyond the simplicity of pull. Hopefully you can see applications for pull systems in your organization beyond just material. This should also give you an inside view to what I do as a Lean Practitioner in manufacturing.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

|

Mercury Wire and OFS share their experiences and learnings from implementing lean and pull systems. Strategies and results at each company vary; commonalities include their focus on providing customer value, nurturing cultural change, and continuing performance improvements.

At a recent two-day AME “kick the tires” workshop held in Massachusetts, two companies, Mercury Wire and OFS, showcased their lean implementations and the pull systems used in their facilities. They also shared their approaches to teaching and training employees about the benefits of pull systems, and one of the companies showed how they have applied pull concepts to project management. This article provides a description of pull system basics, followed by an explanation of how the companies utilize their pull systems as a key element in implementing the lean philosophy.

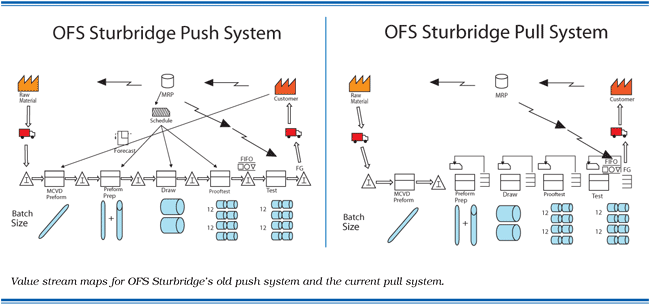

Tim McMahon, OFS lean manufacturing leader, presented value stream maps for OFS Sturbridge’s old push system and the current pull system (see the accompanying illustration).

OFS Sturbridge has gone beyond using this approach to facilitate timely production and material transfers between processes. Increased visibility across the processes allowed the facility to develop teamwork for identifying and eliminating workload imbalances between the processes, helping to reduce backlogs.

Both organizations view pull signals and pull scheduling methods not just as tools but as part of a larger lean philosophy that is used to solve problems and serve customers.

There is a lot of valuable information in this article that goes well beyond the simplicity of pull. Hopefully you can see applications for pull systems in your organization beyond just material. This should also give you an inside view to what I do as a Lean Practitioner in manufacturing.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

Friday, June 17, 2011

Lean Quote: Inspiration

On Fridays I will post a Lean related Quote. Throughout our lifetimes many people touch our lives and leave us with words of wisdom. These can both be a source of new learning and also a point to pause and reflect upon lessons we have learned. Within Lean active learning is an important aspect on this journey because without learning we can not improve.

At 211 degrees, water is hot.

At 212 degrees, it boils.

And with boiling water comes steam.

And steam can power a locomotive.

So many times it is that one extra degree of effort in business and in life that separates the good from the great.

The beauty of 212° is not only the simplicity but also the many applications. You can apply the concept to 212° service, 212° attitude, 212° leadership, 212° kindness, 212° commitment, 212° focus, 212° perseverance and the list goes on. Whatever your passion or profession, how true it is!

The next time you or your team needs inspiration refer back to this video's message:

It's your life. You are responsible for the results. To get what we have never had we must do what we have never done.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

"The one extra degree of effort in business and in life. Separates the good from the great." — Unknown

At 211 degrees, water is hot.

At 212 degrees, it boils.

And with boiling water comes steam.

And steam can power a locomotive.

So many times it is that one extra degree of effort in business and in life that separates the good from the great.

The beauty of 212° is not only the simplicity but also the many applications. You can apply the concept to 212° service, 212° attitude, 212° leadership, 212° kindness, 212° commitment, 212° focus, 212° perseverance and the list goes on. Whatever your passion or profession, how true it is!

The next time you or your team needs inspiration refer back to this video's message:

It's your life. You are responsible for the results. To get what we have never had we must do what we have never done.

Stay connect to A Lean Journey on our Facebook page or LinkedIn group.

Follow me on Twitter or connect with me on Linkedin.

You can also subscribe to this feed or email to stay updated on all posts.

Subscribe to:

Comments (Atom)