The

other day while visiting a local company regarding continuous improvement the

question of how to sustain improvement and avoid plateaus came up. Thinking

that this is a very common question many wrestle with I thought I would share

my thoughts on the matter.

Since

the mid-1990's many US manufacturers have benefited from implementation of Lean

manufacturing methods. Most of these implementations, however, have plateaued

far below their potentials, producing only modest and sometimes transient

gains, and failing to capture the passion and engagement of true Lean

transformations.

Companies

naturally plateau because they get too happy too soon. The earliest plateau occurs after some

initial stability from attacking low hanging fruit. In actuality if you are

focused on developing people it is all low hanging fruit. These plateaus along

the journey to true north can be counteracted by not only teaching the know-how

but teaching the know-why.

Plateaus

are going to happen and management must anticipate them. They are a temporary place to solidify

concepts and learning. Leaders must take the next step to move past their

comfort zone. It is management kaizen that gets you past plateaus. Companies

who break through realize that employee development leads to business (and

Lean) success.

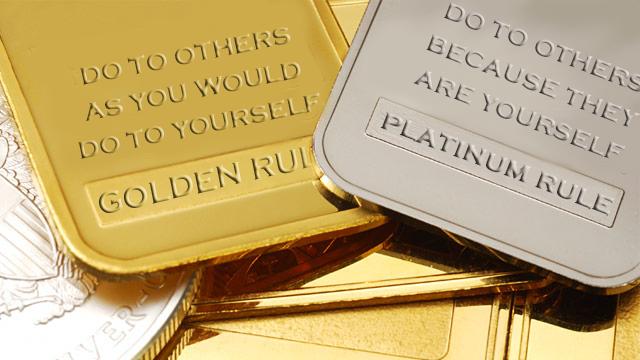

Simply,

sustainability is about lasting change. Sustainability is discussed often and

one of the great issues in management.

We have all seen facts related to the low rates of sustaining change or

seen news about a company who lost its way. Unfortunately, we see all too often

those companies who finally reach #1 to only lose their way.

Complacency

can and will compromise the performance of your organization. Everyone can

become complacent in their particular environment, and there are different

levels of complacency. At higher management positions, complacency may be more

latent. At the line personnel “trigger pullers” level, however, complacency can

have catastrophic results.

When

it comes to complacency with regard to Lean it is often the result of a “We are

Lean” mindset. This leads to a reduction in awareness/focus and leads to a

false sense of security. For Lean to work effectively, the organization must be

constantly focused on continuous improvement and best practice procedures for

providing value. What sets an effective Lean system apart from simply reducing

waste is ingraining continuous improvement thinking into daily practice. Lean

is not about a destination but rather journey.

Charles

Darwin said "It is not the strongest species that survive, nor the most

intelligent, but the ones who are most responsive to change" which holds

true for culture change.

Below

are ten factors that will help any organization make the change they make

lasting.

Capability – Management must employ

the time and resources necessary for change.

Intention

– Determination and drive for the cause is required. You must insist we make the change and be

determined to keep it up.

Success – People feel happier

and perform better when there is a feeling of success and vice versa. Attitude drives performance so managers must

project confidence.

Hard Work – It is hard to keep

it going. This is entropy. Without it, the system runs down.

Emphasis on the team

not the individual

– In the US we love heroes, but actually teams are more fundamental for

long-term survival. Teams need to be

mentored and developed.

Many small wins, rather

than the occasional big win – Small wins keep up the enthusiasm, and certainly add

up. Management needs to continually recognize

small wins.

Attitude toward failure – Everyone fails from

time to time, but what is crucial is the attitude toward failure: do you punish

or do you treat it as part of learning?

Motivation – Sustainability

requires interest and involvement of all employees. Ask "What gets rewarded around

here? Build a culture to support

improvement.

Discipline – Make it a

habit. Without good disciple the system

will not be maintained. Management must

teach discipline and correct lapses with respect for people as they occur.

Performance measures – It is true you get

what you measure, drive good behavior.

Performance measures need to be aligned with what you want to

achieve. Think long term.

There

is no such thing as self-sustainability, it requires ongoing effort.

Sustainable behavior change is not something that occurs as a result of doing a

30 or 90-day program, nor is it something that you master after doing it for a

year. Change takes a daily commitment to put in the time and energy, knowing

that the return on that investment is great.

Lean

(excellence) is a journey that never ends. There will always be a gap between

where you are (current state) and where you would like to be (True North).

Since there will always be a gap, there will always be an opportunity to

improve. Walking the path on a Lean journey can be an overwhelming experience.

Lean

grew out of years of practice and experimentation at Toyota. No matter how much

better they are than their competition, they continue to find more and more

opportunities to improve each and every year. Lean involves the creation and

implementation of continuous experiments to improve your strategies over time.

This means experimenting with every process every day to get it right. We learn

problem solving through hands-on improvement experiments. In Toyota and in lean

thinking, the idea is to repeat cycles of improvement experiments forever.

A

Lean journey is full of steps not all of which are forward. Failure will occur.

Its ok, the purpose is learning, and we learn through experimentation. Trying

new approaches, exploring new methods and testing new ideas for improving the

various processes is exercise for the mind.

So

leaders must create a culture that puts failure in its proper place: a useful

tool for learning, and a natural part of iterative experimentation. Management

must avoid the temptation to harshly judge unsuccessful ideas. A leader who

allows for experimentation sends a clear signal that personnel are encouraged

to find better methods and products.

Organizations

embarking on a Lean journey should follow a disciplined process of systematic

exploration and controlled experimentation. Kaizen is the process which

determines whether processes resulted in improvements. It refers to an on-going

activity by all people (including managers) to relentlessly and incrementally

change and improve practices in small experiments.

The

road to continual improvement is a rocky one with many ups and downs. Value the

incremental improvement approach to continuous improvement. Through simple,

common-sense, and low cost experimentation a great deal of process improvements

can be made. Experimentation is the exercise of a healthy Lean journey.

Understanding this allows one the opportunity to stay on the path along the

journey.